I have been, or can be if you click on a link and make a purchase, compensated via a cash payment, gift, or something else of value for writing this post. As an Amazon Associate, I earn from qualifying purchases. Please read my full Affiliate Disclosure for more information.

When selecting flooring for energy efficiency, focus on heat transfer, insulation value, and moisture control. Look for high R-values and low U-values in subfloor assemblies, and make certain of continuous insulation with minimal thermal bridging. Consider moisture barriers and vapor control, plus low-emissivity surfaces to reduce radiant heat loss or gain. Pay attention to installation tightness, sealing joints, and potential air gaps from floating installs. Curious how to optimize for your climate and budget? There’s more to uncover.

Key Takeaways

- Choose flooring with low thermal conductivity and higher R-values to reduce heat loss and improve warmth.

- Opt for moisture-resistant materials with proper vapor barriers to prevent insulation degradation and mold growth.

- Consider radiant heat benefits: lighter, reflective finishes can reduce cooling loads by minimizing heat absorption.

- Ensure precise installation to minimize air gaps and thermal bridging, especially in floating floor assemblies.

- Balance climate, budget, and durability; factor in long-term energy savings and maintenance when selecting materials.

Understanding How Flooring Affects Home Energy Use

Flooring choice directly influences a home’s energy use by affecting heat transfer, insulation, and comfort expectations. You’ll see measurable effects when comparing materials: lower thermal conductivity reduces heat loss in winter, while dense surfaces can store heat longer. In summer, reflective finishes and light colors minimize heat absorption, lowering cooling loads. Flooring aesthetics influence perceived comfort and utilization patterns, altering thermostat setpoints and occupancy behavior, which feed into energy calculations. Maintenance considerations matter because worn or damp floors degrade insulation and enable air gaps. Data-driven choices should balance cost, lifecycle performance, and comfort, avoiding unnecessary redundancy and focusing on measurable energy impacts.

Key Insulation Concepts and Metrics for Floors

When you consider how flooring affects energy use, insulation concepts and metrics provide the framework to quantify performance between options. You’ll evaluate R-values, thermal resistance per layer, and overall assemblies to compare heat loss and gains. U-values, notations of heat transfer coefficients, reveal how floors perform across conditions. Moisture control emerges as critical: dampness degrades insulation, promotes mold risk, and alters thermal properties. Acoustic insulation matters too, affecting comfort and system efficiency through reduced draft noise and improved radiant temperature perception. Use standardized testing, labeling, and real-world performance data to select floors balancing thermal, moisture, and acoustic metrics for reliable energy savings.

Evaluating Floor Construction and Subfloor Efficiency

To optimize floor efficiency, start by evaluating subfloor R-value strategies to quantify thermal resistance and identify gaps in current assemblies. Consider how the floor assembly air gap influences heat transfer, moisture control, and overall comfort, using data on typical material performance. Finally, review joist/insulation placement to guarantee continuous insulation, minimize thermal bridges, and support accurate load-bearing design.

Subfloor R-value Strategies

Subfloor R-value is a critical factor in overall floor performance, because it directly affects heat transfer between living spaces and the earth or unconditioned spaces below. You’ll evaluate R-value options by inspecting insulation layers, substrate materials, and potential thermal bridges. Quantify performance with labeled R-values, thermal resistance charts, and field tests where possible. Prioritize configurations that minimize moisture-driven degradation, while maximizing stiffness and load tolerance. Consider subfloor moisture risks and implement vapor control as needed. Emphasize durability, choosing materials with proven long-term stability under typical occupancy. Clear, data-backed comparisons support informed decisions about energy-efficient subfloor strategies.

Floor Assembly Air Gap

Floor assembly air gaps play a pivotal role in floor efficiency by mediating convective heat transfer and moisture migration between conditioned spaces and substrates. You assess gap size, continuity, and ventilation to quantify thermal resistance and drying potential. Data show that properly sized gaps reduce subfloor moisture buildup and stabilize temperature gradients, improving comfort with modest material costs. Consider integrating radiant barriers to reflect radiant flux and vapor barriers to impede moisture migration, particularly in humid or cold climates. Verify installation tolerances minimize bridging and ensure durable air channels. This approach supports measurable performance gains without drastic retrofits.

Joist/Insulation Placement

Evaluating joist spacing and insulation placement is essential for predicting subfloor performance, since improper alignment or gaps can create thermal bridges and moisture pathways. You assess joist spacing to minimize heat loss and material fatigue, noting how wider gaps raise floor temperature differentials. Insulation placement matters; you verify that batts or blown-in fill reach the full cavity without compression, reducing convective loops. Document exact measurements, material types, and installation tolerances. Consider airflow between joists and subfloor to prevent mold risk. Align choices with floor coverings, ensuring load distribution remains intact while maximizing overall energy efficiency.

Materials to Consider for Thermal Performance

Materials that improve thermal performance hinge on two factors: heat transfer rates and moisture handling. You’ll compare materials by R-values, density, and moisture management to predict real-world performance.

- Eco friendly materials with proven insulation value

- Moisture barriers and vapor control beneath sensitive subfloors

- Low-emissivity surfaces that minimize heat loss

- Durable, dimensionally stable options for long-term performance

Data shows wood composites perform well when paired with proper moisture barriers, while rigid foams deliver high R-values per inch. Consider lifecycle impact, installability, and compatibility with existing substructures to optimize overall energy efficiency.

Layering and Installation Techniques for Better Heat Retention

Layering and installation techniques directly affect heat retention by controlling air gaps, moisture movement, andthermal bridging; when executed with precise sequencing, they can boost overall R-values beyond material alone. You assess floor layering systematically: identify thermal barriers, vapor control, and air-sealing priorities before placing any material. Installation methods matter as much as product spec, since gaps, compressions, and transition points create measurable heat loss. Use continuous insulation where possible, seal joints, and minimize thermal bridging with properly spaced fasteners. Document tolerances, test for interstitial moisture, and adjust layers based on subfloor conditions to optimize overall system performance. floor layering, installation techniques.

Practical Comparisons: Popular Flooring Options

You’ll compare how different flooring materials differ in R-value, and how those differences translate to steady-room warmth under typical conditions. Installation choices also alter overall warmth, so we’ll look at how seams, underlay, and fastening impact heat retention. This discussion sets the stage for data-driven rankings that balance material performance with practical install considerations.

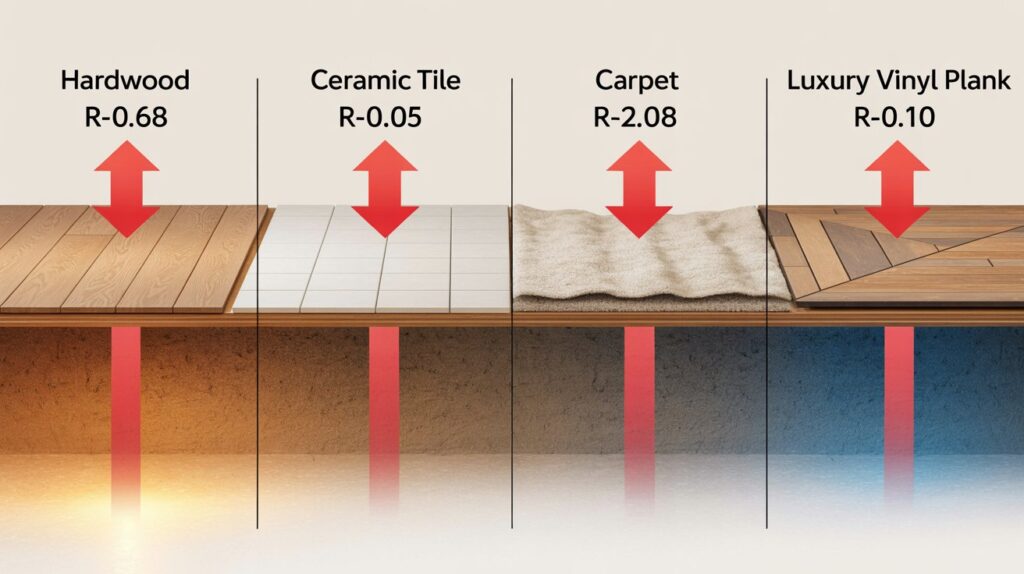

Material R-value Differences

R-value differences among popular flooring options matter for energy performance because they quantify how well each material resists heat transfer. You’ll compare numeric values, noting that higher R-values reduce heat flow and improve insulation when paired with suitable underlayment options and proper flooring thickness. Precision matters: small changes in thickness or layering can shift effective R-values.

- R-values by material and thickness

- Impact of underlayment options on total resistance

- Role of flooring thickness in performance

- Practical thresholds for typical home climates

Installation Impact on Warmth

Although underlayment and installation details can subtly alter overall warmth, the practical effect varies by flooring type because thickness, seam integrity, and air gaps influence real-world heat resistance more than nominal material R-values alone. You’ll notice that thicker options with tight seams and continuous underlayment reduce heat loss more effectively than thinner, gap-prone setups. Materials with higher surface density can feel warmer even if R-values look similar, while floating installs may introduce small air channels that alter warmth. Consider flooring aesthetics and installation cost when weighing trade-offs between comfort, performance, and overall budget. Precision in installation matters as much as material choice.

Smart Budgeting and Climate-Specific Flooring Choices

Smart budgeting for climate-specific flooring starts with quantifying both upfront costs and long-term energy savings, then aligning choices with local weather patterns and home insulation levels. You’ll compare payback periods, R-values, and maintenance costs while considering flooring style and aesthetic appeal.

- Assess initial price vs. projected energy savings to identify value

- Match materials to climate: heat-retaining options in cold zones, cool options where summers spike

- Weigh installation costs against durability and upkeep

- Factor comfort, acoustics, and style into the final flooring style and aesthetic appeal choice

Conclusion

You’ll want your conclusion to be concise and data-driven. In sum: flooring choices measurably influence heat flow, comfort, and bills, with heat transfer coefficients (U-values) and insulation levels guiding decisions. Evaluate subfloor integrity, moisture risks, and thermal mass potential alongside material R-values. Layering and installation can halve energy losses compared to exposed floors. Prioritize climate-aligned options, cost per thermal unit, and durable performance data to optimize energy efficiency without sacrificing comfort or durability.

Leave a Reply